Steel Windows

Steel Windows

The Bethlehem Exhibition

(updated 8 February 2020)

(updated 8 February 2020)

Once "protected by pistol-packing mamas," Bethlehem Steel was central to the success of the United States in peace and war. As you review the photos below, you will not hear what workers and neighbors described as the "constant booming" of the plant. Companion to many generations, today the pulse of the plant can only be imagined by the scope of its gargantuan local footprint, nine and a half miles long.

The easiest way to comprehend the impact of Bethlehem Steel is to watch the PBS documentary on its history (YouTube, ~1 hr. 20 min.) :

Local efforts in preservation and restoration were incomplete as of 2011 when many of these Google Street View photos were taken. Much progress transforming the former headquarters facilities of Bethlehem Steel has been made. New tenants and uses are everywhere. Transformation, however, is a tricky deal that never ends. Working with change, rather than resisting change, is always a challenge.

Here's a flyover of the Bethlehem Steel complex in 2015: YouTube (3:30 min.)

|

| map adapted from brokenbushandroundtop, "This map was used by truck delivery people to identify the various truck dock locations." C. Gallo, 18 January 1979 |

"Bethlehem Steel: the

People Who Built America"

Local efforts in preservation and restoration were incomplete as of 2011 when many of these Google Street View photos were taken. Much progress transforming the former headquarters facilities of Bethlehem Steel has been made. New tenants and uses are everywhere. Transformation, however, is a tricky deal that never ends. Working with change, rather than resisting change, is always a challenge.

Here's a flyover of the Bethlehem Steel complex in 2015: YouTube (3:30 min.)

If you're not an Ozzy Osbourne fan, mute the sound.

Select HD 1080 for clearest viewing.

"Flying Above Bethlehem Steel" by Jerry D.

|

| Outsourced from "Flying Above Bethlehem Steel" above, trees sprout from the furnaces. It appears they germinated shortly after the plant closed. Nature calls this process "succession." |

Exploration of similar abandoned Belgian blast furnace

|

| Click [GSV] to view in Google Street View |

Michael A. Racosky (retired 1960, died 1986) was a machinist and setter in the central machine tool shop. Monster lists a machinist/setter's duties and required skills in 2016 as:

CNC Operator Machinist Job Duties:

- Plans machining by studying work orders, blueprints, engineering plans, materials, specifications, orthographic drawings, reference planes, locations of surfaces, and machining parameters; interpreting geometric dimensions and tolerances (GD&T).

- Plans stock inventory by checking stock to determine amount available; anticipating needed stock; placing and expediting orders for stock; verifying receipt of stock.

- Programs mills and lathes by entering instructions, including zero and reference points; setting tool registers, offsets, compensation, and conditional switches; calculating requirements, including basic math, geometry, and trigonometry; proving part programs.

- Sets-up mills and lathes by installing and adjusting three- and four-jaw chucks, tools, attachments, collets, bushings, cams, gears, stops, and stock pushers; indicating vices; tramming heads.

- Loads feed mechanism by lifting stock into position.

- Verifies settings by measuring positions, first-run part, and sample workpieces; adhering to international standards.

- Maintains specifications by observing drilling, grooving, and cutting, including turning, facing, knurling and thread chasing operations; taking measurements; detecting malfunctions; troubleshooting processes; adjusting and reprogramming controls; sharpening and replacing worn tools; adhering to quality assurance procedures and processes.

- Maintains safe operations by adhering to safety procedures and regulations.

- Maintains equipment by completing preventive maintenance requirements; following manufacturer's instructions; troubleshooting malfunctions; calling for repairs.

- Maintains continuity among work shifts by documenting and communicating actions, irregularities, and continuing needs.

- Documents actions by completing production and quality logs.

- Updates job knowledge by participating in educational opportunities; reading technical publications.

CNC Operator Machinist Skills and Qualifications:Conceptual Skills, Process Improvement, Verbal Communication, Functional and Technical Skills, Controls and Instrumentation, Supply Management, Tooling, Coordination, Inventory Control, Attention to Detail, Judgment

- Accomplishes organization goals by accepting ownership for accomplishing new and different requests; exploring opportunities to add value to job accomplishments.

Richard H. Kleintrop worked as First Floor Foreman in the central machine tool shop for 45 years. Watching his grandson play baseball gave him great joy.

|

| Richard H. Kleintrop (31 March 1916 - 19 March 2012) |

Raymond Howard Hinkle (died 12 July 1971) worked at the central machine tool shop for a number of years.

|

| Shown below is the "No.4 Shop" (# 173) |

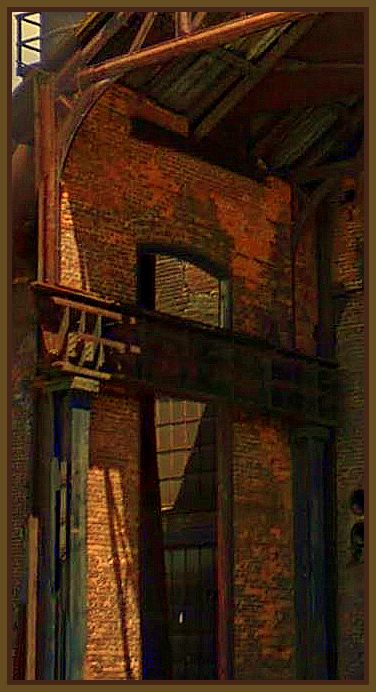

The "No. 4 shop" housed many Bethelehem Steel activities. The image shows a part of the building housing "Construction/Air Condit"[ioning?]. Also located within these walls were the Safety Shop and the Bearing Center:

|

| [GSV] |

|

| [GSV] Listed as "abandoned" on the map above, the function of this building is unknown. |

|

| [GSV] Hooked Everything at a steel plant is on a grand scale. This gantry crane could lift tons and tons of steel products. |

|

| [GSV] |

|

| [GSV] |

|

| [GSV] |

|

| [GSV] ArtsQuest Center, reflects one of the best redevelopment projects I've seen anywhere! to be continued.... |

Comments

Post a Comment

Comments will not appear immediately. They are sent to the blog author for "moderation." If they are relevant to the content, it is more than likely they will appear. Suggestions welcome!